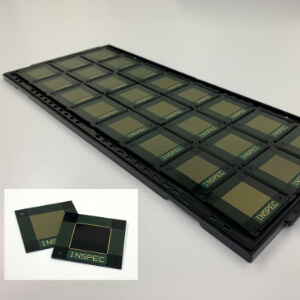

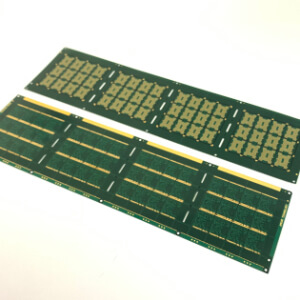

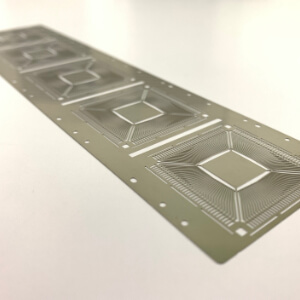

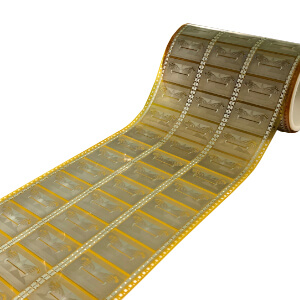

JEDEC TRAY(S)

Automatic transport inspection product

BP7200

Inspection of each EDEC tray

Achieves ultra-high-speed inspection of 1.2 seconds per piece (* 1)

* 1 When using a tray with a piece size of □ 10 mm and 10 pieces x 24 pieces

| PRODUCT OUTLINE | |

|---|---|

| Equipment size | W3,060 x D1,650 x H1,970mm |

| Applicable board size | □10mm~□120mm |

| Minimum defect size | □10um~ |

| Target inspection | |

|---|---|

| Wiring inspection | |

| Hole inspection | |

| Plain inspection | |

| Target product name |

|---|

|

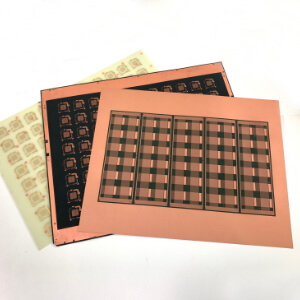

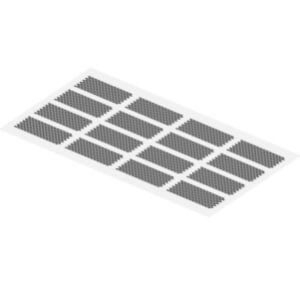

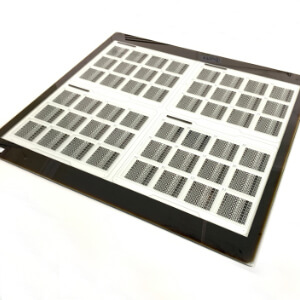

Substrate AOI

SX1000

Compact body that does not take up space.

Inspection is possible even in the state of seat, frame and tray.

| PRODUCT OUTLINE | |

|---|---|

| Equipment size | W890 x D1,610 x H1,600mm |

| Applicable board size | 300mm x 400mm |

| Line/Space | 15um/15um ~ |

| Target inspection | |

|---|---|

| Wiring inspection | |

| Hole inspection | |

| Plain inspection | |

| Target product name |

|---|

|

Soft veryfy system

SV100

Verification work is possible with inspection results and NG cutout images.

Verification work is possible even in remote areas (general office / overseas, etc.)

| PRODUCT OUTLINE | |

|---|---|

| Equipment size | - |

| Applicable board size | - |

| Target product name |

|---|

|

Data mapping system

DM100

Inspection result aggregation confirmation software

You can check the result at a glance on the tabulation screen

| PRODUCT OUTLINE | |

|---|---|

| Equipment size | - |

| Applicable board size | - |

| Target product name |

|---|

|

Defect automatic classification system

Pentagon

Inspec's original defect screening algorithm "iDSA" significantly reduces verification man-hours

| PRODUCT OUTLINE | |

|---|---|

| Equipment size | - |

| Product roll width | - |

| Target product name |

|---|

|