Welcome to inspec Inc.

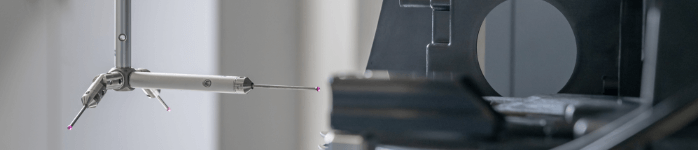

Inspection equipment and exposure equipment are introduced at the virtual exhibition.

Click on each product to view the product details.

Each equipment can also be selected from the manufacturing process of the printed circuit board.

Chat and online consultation are available, so please contact us.

Product list

Product list

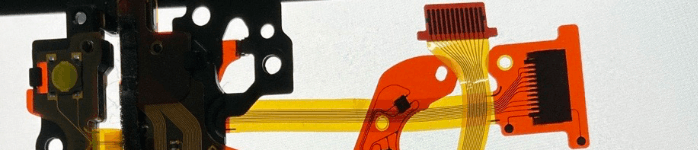

Inspec equipment used in manufacturing process of flexible circuit board

-

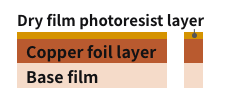

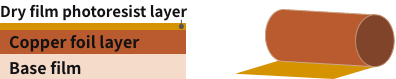

Attachment of copper foil

Copper foil is attached to the base material.

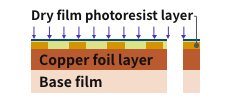

Photoresist lamination

Laminate the photoresist for etching.

-

Development

Melt the unsensitized film to reveal the circuit pattern.

-

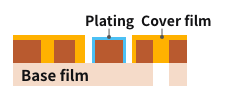

Adhesion of insulation layer

Adhere the insulation layer except for the terminal adhesive area.

-

Outline machining (Various punching)/ Electrical inspection

Punching according to the blueprint to make individual products.

Connection of the circuit is checked via electrical inspection.

Crimping of reinforcing materials, component mounting, special machining/processing, final inspection.

Insert reinforcing materials and mount the components.

Final inspection and packing are carried out.

-

Product shipment, Completion